Mining

For more info contact us

For the mining industry NTE Process has developed a series of efficient processing and product handling technologies aimed at improving plant productivity, such as:

- truck and train loading

- vibrating screens with condition monitoring

- batch & continuous feeders

- weighing solutions

- continuous dense & dilute pneumatic conveying systems *

- pulverising mills

- bulk bag loading & unloading

- air filtration (dust collection).

In particular, NTE Process designs reliable pneumatic conveying systems which make it possible to satisfy one of the main needs of the mining industry, i.e. the presence of large quantities of materials (coal, minerals, lime, etc.) that have to be delivered over great distances.

The solution provided by NTE Process is characterized by very low conveying speeds creating very dense product caps that move compactly along the line. Through the use of Air Assist® technology, a patented system strategically positioned along the transport pipe into which it injects air at a controlled pressure and volume, air consumption is considerably reduced, resulting in significant energy savings. This technology is particularly suitable for preserving fragile products, minimizing segregation of mixed products and preserving lines from product abrasion. The Air Assists® are suitable for both pressure and vacuum systems and are also particularly suitable for retrofitting existing systems to improve their performance, as well as to preserve the characteristics of the products, both in the tank and wagon loading and unloading phases, both for sending to ensilage and bagging stations.

Furthermore, NTE Process provides dust filtration systems combined with the “DSI” technology of dry injection of sorbents for the reduction of harmful emissions, offering an economic solution, easy to install, even in the case of existing systems or upgrades. This solution is more effective than traditional technologies also thanks to the use of special Injection Lances (Eco-Lance®®) able to contribute to the reduction of the use of sorbents up to 50%.

The sorbents, normally hydrated lime, sodium bicarbonate, trona, activated carbon, are continuously transferred from the storage silos to the injection nozzles strategically positioned along the flue duct, consequently reacting with the polluting gases and ensuring the effective abatement of emissions.

Finally, there are a number of special applications successfully installed in the mining industry, such as:

- hydrated lime and soda ash dissolving;

- dense and dilute pneumatic conveying systems for copper concentrate, soda ash, lime, lime oxide, hydrated lime, sodium bicarbonate, activated carbon, aluminum, cement, borium, silica, urea, zinc, and other minerals;

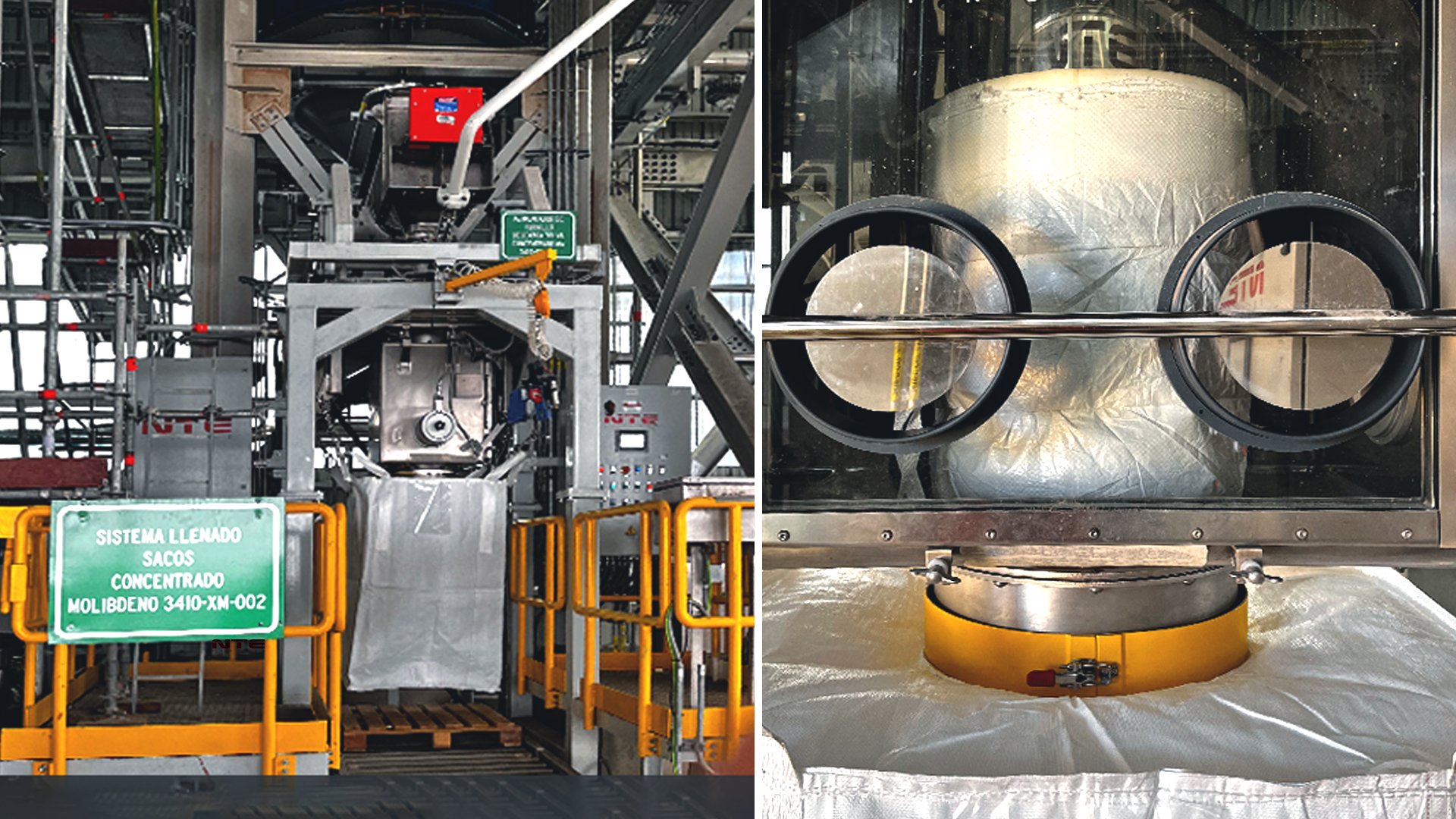

- dust-tight, high-containment bagging stations (OEB) for molybdenum, lithium carbonate, activated carbon, cement, aluminum and other mineral products;

- harmful emission control systems (SOX, NOX, HG, HCL mitigation);

- gas cleaners (wet scrubbers).

The NTE Process experts will work alongside you to make your mining operations more sustainable and efficient by designing and supplying extremely versatile, reliable and durable systems even in the most difficult operating conditions.

Want to know more about this solution?

Contact us