Slurry Mixing

For more info contact us

NTE Process provides two different innovative technologies when it comes to solid-liquid mixing:

VACUCAM®

Powered by Semi-Bulk Systems, Vacucam® is a special ejector-mixer for completely dispersing powders into liquids.

The conditioned powder is conveyed into the mixer by a near-perfect vacuum, which is created when pressurized fluid is discharged as a high-velocity into the ejector. The Vacucam® system achieves high-speed, instantaneous and complete wetting by bringing together conditioned powder and highly atomized liquid from two separate streams, incorporating particles of liquid with particles of powder. The reactive surface areas of both the powder and the liquid are maximized before intimate contact is actually made. The result is consistently uniform, superior wetting without the agglomeration or “clumping” usually associated with conventional mixing methods (e.g. through a mixing ribbon). NTE Process can design and integrate the Vacucam® in-line system to feed finished slurry into multiple locations, according to your needs, such as storage or mixing tanks. The entire process can be physically separated and remotely controlled. The ejector-mixer can be mounted directly on tanks or integrated with an existing process.

Advantages:

- high-speed, instantaneous and complete mixing;

- Vacucam® makes it perfect for fluid mixing too. Highly atomized liquids can be brought together from two separate systems for batch-to-batch consistency and uniform mixing;

- optimization of process efficiency and reduction of production costs;

- It is a versatile product that guarantees the complete dispersion of numerous products including soda ash, cobalt, manganese, lithium hydroxide, powdered activated carbon, but also powdered whey, gelatin, pectins, gums, starch, sugar, sweeteners, thickeners, carbonates and other ingredients used for chemical production.

- Vacucam® is also suitable for FGD processes in power plants, removing SOx, mercury and the reducing NOx.

ROTOSOLVER®

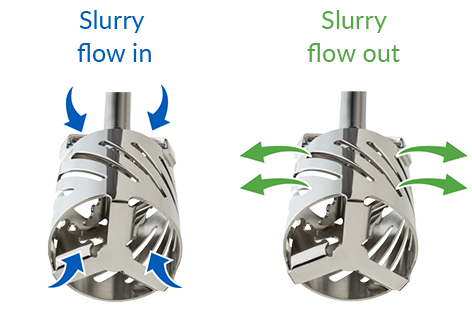

Powered by Admix Inc., Rotosolver® is an in-tank disperser designed for fast incorporation of powders into liquids. The patented design of its shear head is the key to achieving homogeneous dispersions in less time, compared to other mixers on the market. Shorter batch times, higher quality dispersions, and lower energy consumption are some of the key performance advantages that the Rotosolver® delivers. Indeed, Rotosolver® produces high flow resulting in batch process times that are much faster. In addition, its mix head design generates four stages of mixing action for optimal for dispersion:

- Product flow is drawn into the mixing head from above and below. The resultant flow creates vigorous tank motion, pulling materials and powders from the top of the tank surface (typically the toughest to disperse), instantaneously exposing them to shear zones in the Rotosolver® shear head, where these materials are mechanically ripped apart (dispersed).

- The two high-velocity, counter-current streams converge within the shear head, creating high turbulence and hydrodynamic shear.

- Pressure, created by the two streams, forces material out the side slots of the shear head, where the resulting radial streams are subjected to further mechanical shear, as material passes through the edges of the slots in the chamber wall.

- The high velocity radially discharged streams impact the slower moving tank flow for additional hydrodynamic shear and circulation, thus ensuring high flow, with no dead spots in the mix tank.

Advantages:

- reduction of energy consumption up to 30%;

- improve dispersion quality up to 10%;

- increase overall shear rates;

- reduce batch times for increased capacity;

- improved cleanability;

- retrofit available for existing installations;

- wet out and disperse Carbopol®, Methocel®, Opadry®, Avicel®, CMC, sugar, xanthan and guar gum, soy proteins, starches, pectin, carrageenan and other “tough” hydrocolloids and ingredients.

Want to know more about this solution?

Download the brochure