Food

For more info contact us

The NTE Process solutions for the food industry has been designed to answer to a number of requirements which are fundamental to obtain a quality finished product, such as the respect of production hygienic standards, the gentle handling of raw materials with dust-tight systems, accurate dosing of recipes especially where the production needs to be free from allergens together with the reduction of segregation, in case of mixtures, and the degradation of materials.

It is precisely with this in mind that NTE Process has developed its own process solutions ranging from dense phase pneumatic conveying to the dosing and mixing of powders and granules, as well as liquid injection, storage, bagging and in-line formulation up to packing. The aim is maximum efficiency and flexibility of the systems, in full compliance with ATEX, MOCA and GMP guidelines.

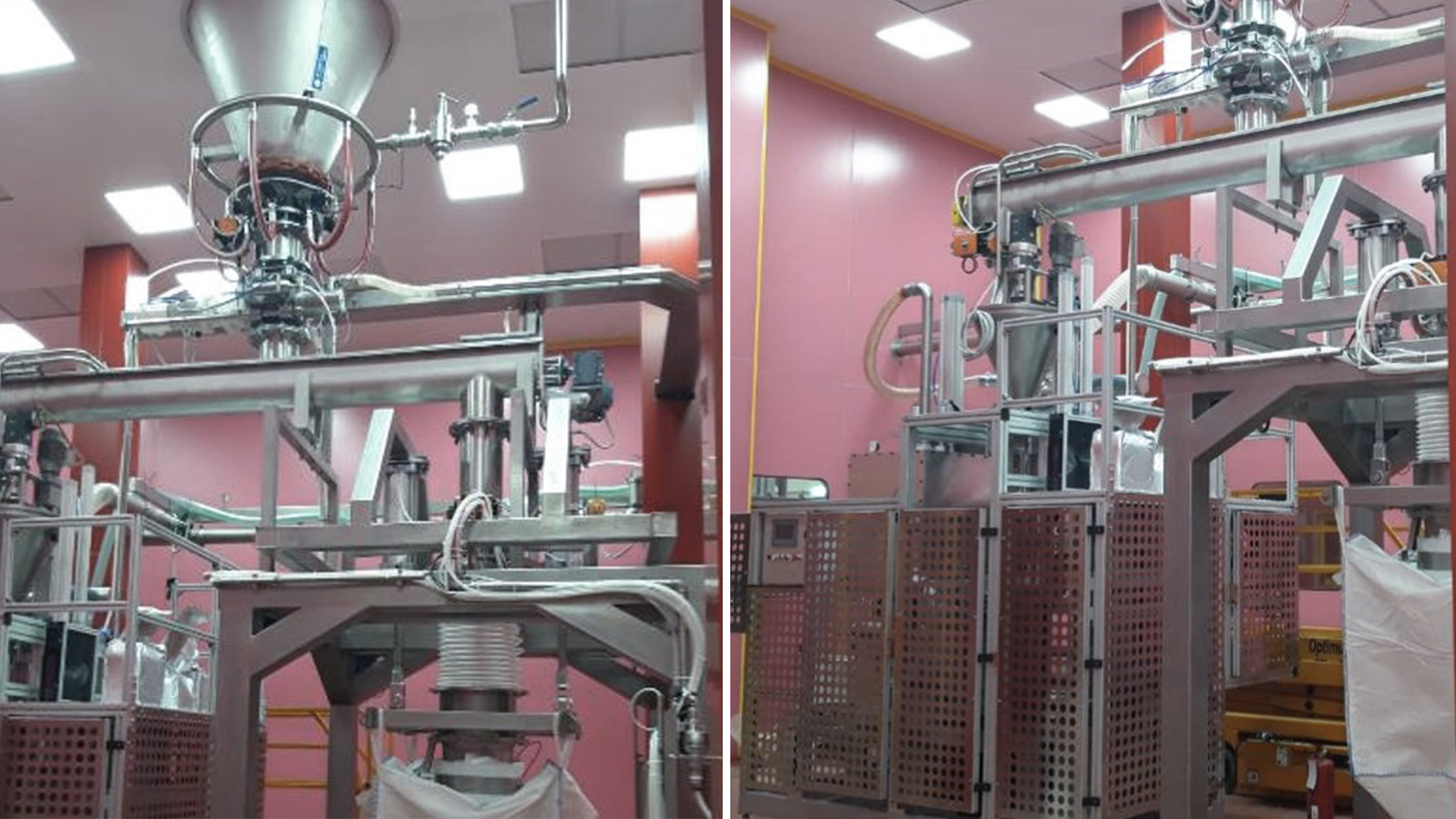

Among the process solutions for the food industry, the success of NTE Process passes through the development of the revolutionary Wonderbatch®, a technology which guarantees a rapid changeover in the in-line formulation and in the management of raw materials in big bags, sacks and IBC containers. This solution can be combined with dense phase pneumatic conveying systems with patented Eco-DenseTronic® technology and pneumatic mixing using Air Mixer M244 and Jetmixer®M531.

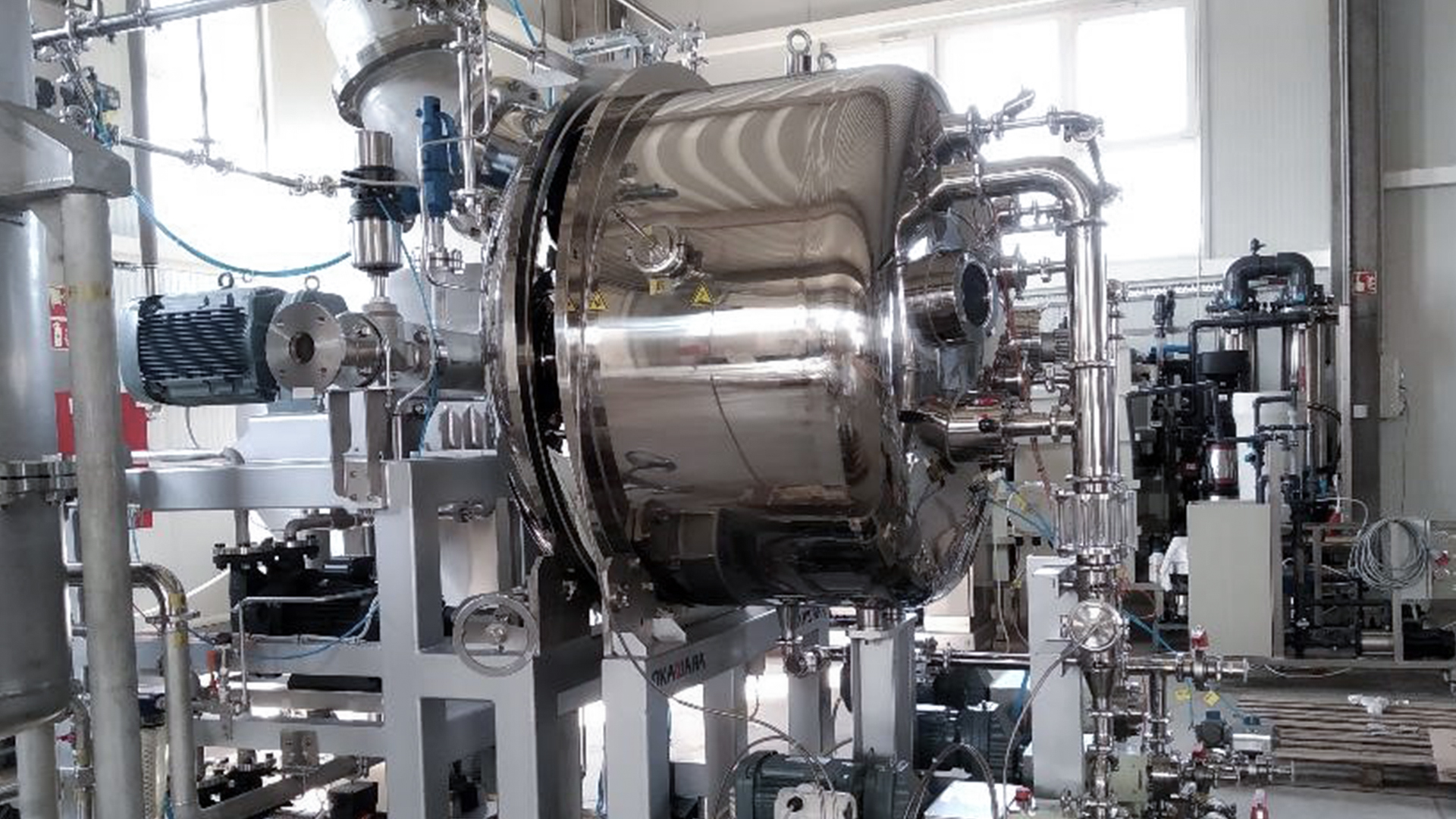

The company extensive process know-how in the food industry is also based on collaboration with international partners with specific reference to drying, spray drying, granulation and grinding of a vast range of products.

In addition, a unique process is available which includes an in-line mixer based on a special VACUCAM® Ejector which is the most effective method for the complete dispersion of whey and milk proteins, whey powder, gelatin, pectins, gums, starch, sugar, sweeteners, thickeners and all other dry ingredients typically used in the production of seasonings, sauces, desserts, ice cream and other food products.

The fields of application of the process solutions for the food industryies provided by NTE Process are very varied and are aimed at primary customers in the following sectors:

- Infant & Baby food: receiving and storage systems for nutrients and supplements, drying systems, dosing and mixing of ingredients, in-line formulation of recipes, traceability and automation, transport and bagging systems that not alter the product bulk density through dense phase technology with Air Assist®, packing lines.

- Milk processing: MOCA certified bag and big bag unloading stations, conveying systems for powder milk with a high fat and lactose content, and pneumatic mixing in silos with additives and ingredients for conservation.

- Cereals: effective and homogeneous mixing of raw and intermediate materials, even dry and viscous liquids.

- Pasta industry: complete solutions from the unloading of tankers to storage silos, from the gentle pneumatic conveying of the main and minor ingredients to best preserve the characteristics of each product, dosing and mixing of flours, vitamins and minerals to the packing lines.

- Production and handling of yeast and starches using dense phase systems and pneumatic mixers.

- Rice industry: dense phase conveying, also of parboiled rice and white basmati rice, thai, etc., in a versatile and clean way and with minimal degradation of the beans.

- Chocolate industry: dense phase pneumatic conveying systems for highly abrasive cocoa beans and high fat content cocoa powder, dosing of sticky ingredients such as raisins, candies, fruit pieces, oat flakes and various liquids then mixed and prepared to feed the production of bars.

- Coffee industry: transport and storage of green coffee, transport and storage after roasting, handling after grinding, complete lines including pneumatic blending for instant coffee. In addition to the revolutionary technology of degassing and simultaneous mixing by means of JetMixer®M531 in vacuum and fed with nitrogen at specific temperatures for stripping the CO generated in the grinding.

- Premix for the ice cream and cake industry: mixing of semi-finished products and preparations and transfer to the final destination, such as packing and ensilage, minimizing the risk of segregation of the mixed batches.

- Supplements and instant drinks: pneumatic conveying of raw materials, batch or continuous dosing and mixing.

- Dragees and tablets: handling from the hopper of origin to the coating machines through gentle vacuum dense phase conveying with the patented Air Assist® technology which minimizes breakage of the transported product.

- Confectionery, biscuits and snack industry: handling of different ingredients, with minimal impact even on fragile products, and management of recipes without risk of contamination between single batches and allowing the change in line between one big bag and another.

- Spices and condiments: turnkey solutions from the pneumatic conveying of raw materials from silos or bag and big bag unloading stations to the receiving hoppers, precise dosing and delicate mixing, packing lines.

NTE Process technologies make it possible to maximize the efficiency of the systems in terms of energy consumption, guarantee hygiene in contact with food and avoid its degradation as well as preserving organoleptic properties, coloring and aromas.