Rubber & Tyre

For more info contact us

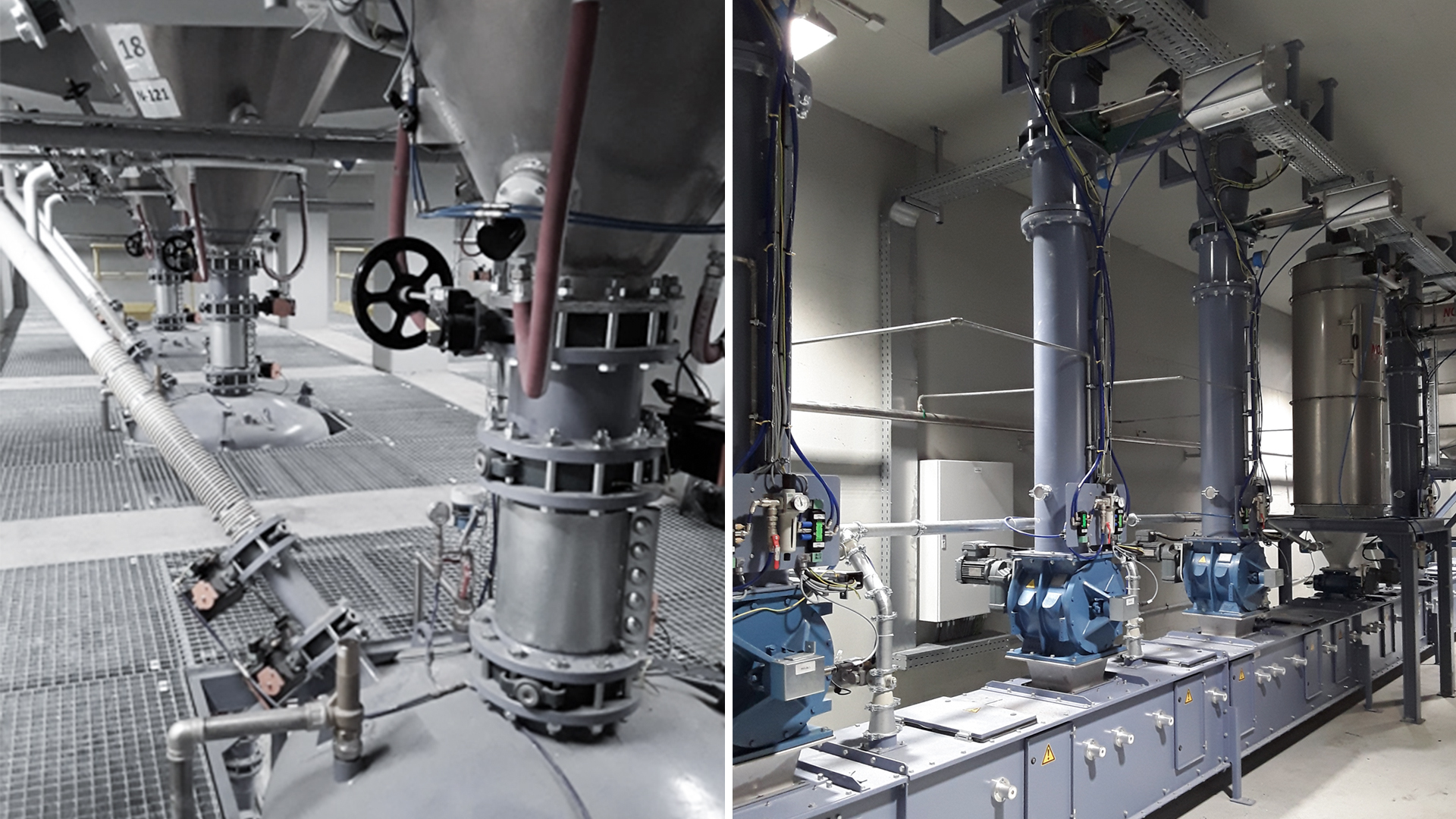

Over the years, NTE Process has developed many technologies for the rubber/tyre sector (tyres and compounds production) specifically for high value-added quality production, and has become a unique partner offering complete turnkey systems that are flexible and efficient.

These are the reasons why the main market players have chosen NTE Process technologies for rubber compounding and the production of tyres, automotive components and electrical cables: areas in which safety and quality are essential for high performance.

The main NTE Process solutions are:

- storage of raw materials for rubber compounds in silos

- “no purge concept” dense phase pneumatic conveying with Air Assist® technology for powders and granules (carbon black, silica, bulk chemicals, etc.) to mixing lines

- high precision powder dosing and oil injection systems for loading mixers

- filtration and dust collection

- polymer dosing through rubber cutters and belt conveyors

- rail and truck unloading using the NTE Process Boot-Lift M529

- automation and control systems

- in-line formulation for additives (innovative technologies for pigment room automation)

- dedusting systems for storage silos and daybins.

NTE Process technology for dense phase pneumatic conveying, both of the pressure and suction type, has proven to be the best for primary products for the production of tyres because it guarantees:

- the integrity of carbon black pellets following dense phase pneumatic conveying (fine fraction < 1%);

- no premature pipe wear in the case of the pneumatic conveying with Air Assists® of silica (fine, granular, silica chunk);

- dust-free handling of big bag unloaders and bag unloaders for carbon black, silica, zinc oxide.

The patented NTE Process dense phase pneumatic conveying with Air Assists® uses a small amount of compressed air to transport large quantities of product even over long distances.

It is ideal for fragile products (carbon black, etc.), or abrasive products (silica, etc.).

In the ‘NO PURGE’ version, the system restarts at each cycle with the line full of product, avoiding the most critical line cleaning phases.

Particularly suitable for low speed conveying systems (< 5 m/s) and involving long distances (over 150 m), the patented Air Assist® technology has been innovated by a new patent, “Eco Dense-Tronic®”, which, thanks to the use of Artificial Intelligence, allows for a 40% increase in efficiency and a reduction in energy consumption of up to 70%*. For each plant equipped with Eco Dense-Tronic®, a C02 saving equivalent to almost 3,000 new trees planted* is possible in one year.

(*Results achieved with specific plant configurations.)

In addition to being “green”, this new technology also improves and optimises product control and speed by reducing the creation of fine particles, as well as abrasion on conveying lines. Thanks to Artificial Intelligence, line pressure and flow are continuously monitored, so the conveyed product keeps its characteristics intact (fine fraction <1%*). Moreover, the system also features a self-diagnostics and self-learning system capable of adapting to product changeovers and any changes in the conveying conditions.

NTE Process also offers the patented pneumatic blenders – Air Mixer M244 and Jetmixer® M531 – with no mechanical parts in contact with the product. Timed pulses of compressed air gently lift the materials upwards and outwards in a continuous circular motion. By combining air mixers with the NTE Process Liquid Injection Skid M535, liquids are injected directly through the aeration valve that generates the blending. This patented technology improves the dispersion of the liquid in powders (silica, carbon black, etc.) by using air as the distribution vehicle. The system can inject up to 6 liquids simultaneously, preventing powder from building up on the nozzle and the drop effect that usually characterises traditional injection systems.

The main NTE Process applications for the “Rubber&Tyre” sector are:

- Powders and Granules (carbon black, silica, small chemicals, etc.): “no purge” dense phase pneumatic conveying with Air Assist® technology for hopper batching and compound preparation

- Additives, micro ingredients: in-line formulations and innovative technologies for pigment room automation.

- Silica (fine, granular, silica chunk): pneumatic conveying with Air Assist® without premature pipe wear.

- Talc, carbon Black, Silica, Zinc Oxide: dust-free management of big bag unloaders and bag unloaders.

Want to know more about this solution?

CASE STUDY - ECO DENSE-TRONICCASE STUDY - DOSING, WEIGHING, MIXINGCASE STUDY - TRUCK/RAILCAR UNLOADINGDownload the brochure